NT Build 492: An Option for Concrete Durability Testing You’ve Never Heard Of

The Chloride Migration Coefficient from Non-Steady-State Migration (NT Build 492) test, from the NordTest family of test methods, is not yet widely used in the United States. An alternative to ASTM C1202, the NT Build 492 laboratory test is used to determine the chloride migration coefficient in concrete and mortar. This coefficient can then be used to assess concrete quality and durability.

If you need concrete testing for a bridge or other structural project, NT Build 492 might be the best laboratory testing option for verifying resistance to chloride penetration. The test is reliable and relatively inexpensive. Because NT Build 492 is not well-known in the U.S., I’d like to share a bit more about this new and unique EBA service capability.

Why is the test needed?

Infrastructure owners are not only responsible for ensuring that a structure is designed for durability, but also for managing any durability issues throughout the life of the structure. The NT Build 492 test is important for evaluating the long-term durability of roadway bridge decks, piers, and other concrete structures affected by chlorides and other oxidizing agents. In other words, it helps determine if the concrete to be used will be able to resist deterioration from exposure to chloride.

Although concrete may appear strong and solid to the naked eye, on a microscopic level, concrete looks like a sponge, full of pores and aggregate. Chloride can penetrate concrete and impact its steel reinforcement by diffusing through the concrete’s system of saturated pores.

In a typical northern climate, for example, bridge structures are subjected to chloride from the road salt used to deice roads. Chloride penetrating the concrete results in oxidation (corrosion) of the steel reinforcement. Without costly repairs, this corrosion could ultimately cause the structure to fail or significantly reduce the life of the structure.

How is the test performed?

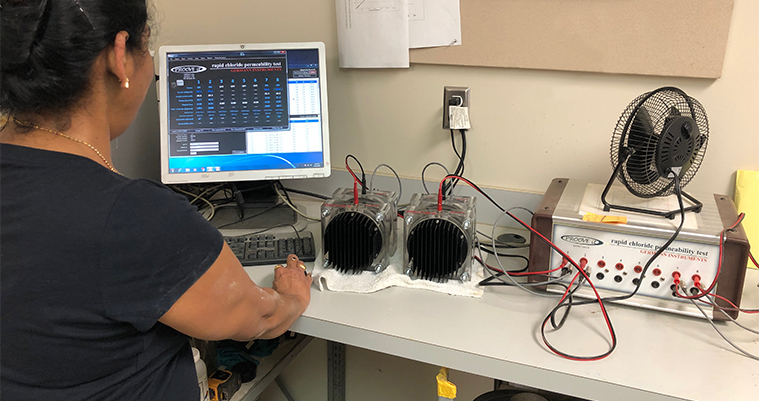

The NT Build 492 test is usually performed on concrete cylinder specimens prepared at the project site and then trimmed in the laboratory using a masonry saw. The cylinders are typically cured for 28 days before performing the test. The test can also be performed on 4-inch-diameter drilled cores.

The specimens are pre-conditioned in a vacuum chamber then sealed to only allow chloride to penetrate at the sample ends. The samples are placed in cells with reservoirs on each end. The reservoirs are filled with anolyte (NaOH) and catholyte (NaCl) solutions, respectively. A specified voltage is applied across each sample to drive the chloride migration.

At the end of the test, the samples are removed from the cells and split using a compression machine. The split face of each sample is sprayed with AgNO3, which reacts with the chloride to form a distinct boundary depicting the limit of the chloride penetration through the sample. The depth of the chloride penetration is measured, and the chloride migration coefficient is determined from the data.

How is NT Build 492 useful for your organization?

The chloride migration coefficient is a valuable tool for managers and engineers to evaluate concrete’s durability and long-term performance. The test can be used to identify weaker areas of concrete, which can then be flagged and repaired during construction if necessary. As a result, owners can be confident that their structures will perform for the minimum required life span without costly repairs due to steel reinforcement corrosion.

EBA can now perform NT Build 492 testing in our AASHTO-accredited materials testing laboratories. Contact EBA to learn more about the test and our service offerings!

Jason Kolenda, PE, is the geotechnical engineering and laboratory testing department manager for EBA Engineering, Inc. He can be reached at 443.277.1579, jason.kolenda@ebaengineering.com, or on LinkedIn.