How to Leverage P2E2 to Dramatically Cut Operating Costs for Water/Wastewater Treatment

If you are a water/wastewater facility owner or manager, I can guarantee that you have experienced a sometimes-alarming trend that is likely to continue: increasing energy, chemical, and raw material costs along with increasing energy use at your facility. As equipment and facilities age, operations and maintenance (O&M) expenses increase. These increasing O&M expenses combined with rising energy/materials costs often have a negative impact on production, end user costs, and management decisions.

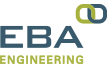

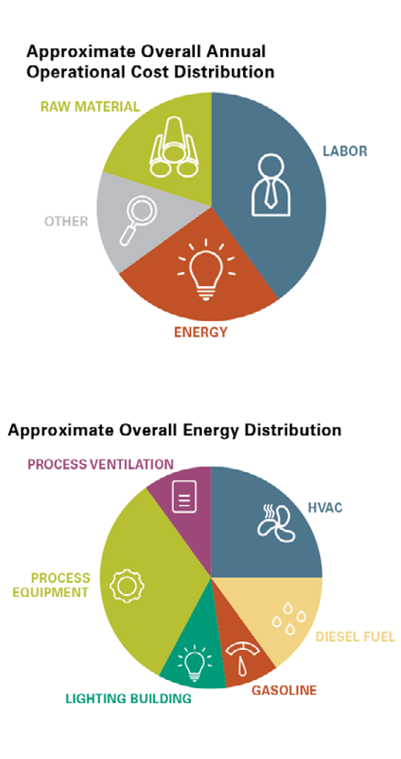

Fortunately, there’s a way to help your organization minimize environmental or energy costs and reduce overall operating costs. For small businesses, energy costs hold the greatest potential for bottom line savings. Energy costs typically account for 10 to 25 percent or more of the total annual operating costs. For example, a food processing facility will consume approximately 70 percent of total energy costs for process equipment and HVAC. Next to labor, energy costs currently rank as the number one issue for industries and business primarily because these are costs that can be controlled.

Has your water/wastewater facility considered an energy audit or Pollution Prevention and Energy Efficiency (P2E2) site assessment to save operating costs? If not, read on to see why a P2E2 assessment is a greatchoice for improving your organization’s bottom line.

P2E2 Site Assessment Program

The P2E2 Site Assessment Program was instituted in Pennsylvania to help companies and organizations perform energy and pollution prevention audits for any industry with a state air, water, or wastewater permit or a commercial processing facility with the same permits employing less than l00 employees.

The program provides a tool for managers, owners, and operators of these businesses to reduce operating costs by decreasing chemical use, reducing utility bills, and optimizing facility operations including the water and sludge waste streams.

The program provides a tool for managers, owners, and operators of these businesses to reduce operating costs by decreasing chemical use, reducing utility bills, and optimizing facility operations including the water and sludge waste streams.

The P2E2 site assessor will review the facility’s water or wastewater treatment processes and recommend strategic modifications and upgrades. Because repairs and upgrades will require capital investment, a P2E2 assessment includes an evaluation of potential funding resources, such as grants and rebates, that may be available to help offset capital costs.

P2E2 provides a return on investment in more sustainable process operations, less energy consumption, and reduced chemical reliance—generally in less than 1 year—and savings for years to come.

Example solutions include:

- Implementing more efficient pumps/motors or equipment to conserve energy and reduce costs.

- Replacing chemical use with biologicals or other sustainable products that have less impact on the environment and operators.

- Reducing chemical use through process changes.

- Reducing energy bills through low-cost or short-term equipment upgrades and/or optimizing equipment use.

- Optimizing the actual process for both liquid and sludge streams.

In my experience, the average savings from P2E2 opportunities recommended and implemented range from $5,000 to $12,000 or more annually. The engineering services for the studies have paid for themselves in less than 2 years based on this average savings.

P2E2 Site Assessment Features

A P2E2 assessment typically takes just a few hours on site. The site assessor will generally exchange information with the owner and operators about the energy using systems at the plant and discuss plant operations, physical layout, and projected outlook for future use. The assessor will review information on the utility bills, blueprints, and O&M manuals and conduct a thorough analysis of the treatment process, all motor-driven equipment, and the control building lighting and HVAC. The site visit will also include interviews with plant maintenance staff and management staff to focus the P2E2 and obtain additional information.

The site assessment report can be used for strategic planning as well as reducing O&M costs. The assessment will:

- Evaluate the most significant energy-using processes and recommend energy-saving opportunities for process equipment, HVAC, motors, and lights.

- Analyze opportunities to recapture wasted or excess energy sources to supplement existing sources.

- Recommend cost saving opportunities that follow standard O&M practices for energy management to be used in the plant’s existing O&M plan.

- Examine the environmental impacts for all processes, procedures, wastes, and energy uses at the facility and recommend solutions.

- For each recommendation, provide a financial savings estimate including the annual average cost savings.

- Give clients decision-making information by identifying the P2E2 opportunities, construction estimates and lifecycle costs, potential funding sources, and simple payback periods for each opportunity.

The site assessor will review a draft of the report with the facility operator/manager to ensure that it meets their goals and objectives. Some clients desire to address specific engineering strategies during the study, and these are worked into the overall site assessment and report.

Hiring a Qualified Site Assessor

It is critical that businesses hire a certified and qualified site assessor. Some site assessors are more familiar with specific systems: electrical and HVAC, lighting, motors, air compressors, food processing, water treatment, or wastewater treatment. Therefore, selecting the proper site assessor is critical to the client’s objectives for the P2E2 study. I recommend that anyone interested in hiring a consultant to complete this type of study review their previous experience as part of the selection process to see the type of work that the site assessor will deliver.

EBA’s team includes trained, experienced wastewater treatment plant operators with true industry expertise. We have been performing energy audits for more than a decade and have performed many P2E2 site assessments. We serve clients in the water/wastewater treatment plant (municipal and industrial) and commercial food processing industries. We would welcome the opportunity to speak with you further about our services!

Stephen Zeller is a senior project manager for EBA Engineering, Inc., and a certified P2E2 site assessor. To learn more about EBA Engineering’s P2E2 solutions, contact him at 717.510.9644, steve.zeller@ebaengineering.com, or on LinkedIn.